Innovation Center

Located just outside of downtown Chicago is Pretium’s innovation center, a facility dedicated to helping customers develop their next product. We have every bottle from our stock line and select competitor bottles that can be viewed in our market segment room.

The Design Room: Work together to design a bottle on the spot by walking through different aspects of our containers, answering questions, and identifying specific capabilities.

The Market Development Room: Gain an edge on the competition on our simulated store shelves, seeing how your bottle displays versus existing products. Any requested modifications can be made back in the design room, facilitating the iterative bottle design process.

Collaboration Spaces: We know collaboration is key to developing winning products that stand out against the competition. Our large conference rooms and smaller customer offices are available for wide collaboration or private, internal meetings. Our space is your space!

Innovation Lab

Innovation is a core competency at Pretium, and you will see evidence of that as you work with different departments and functional teams. For example: our new Innovation Lab creates an opportunity to bring new products and high-performing designs to market faster with single-cavity prototyping capabilities.

Learn More

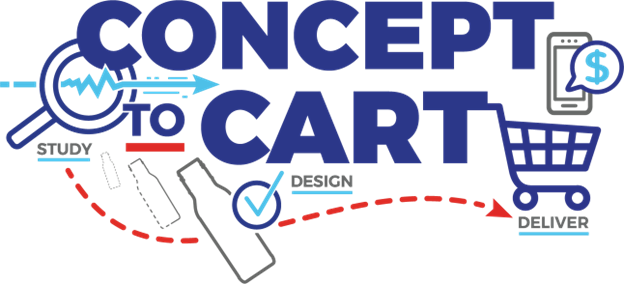

Custom Molding

When you can’t find a stock package that meets your needs, Pretium can create a custom mold quickly and economically. Custom bottles and jars differentiate your product and build your brand equity.

Learn More

Printed Folding Cartons

Through our Ediprint division, Pretium can offer full-color offset printing of cardboard and paperboard cartons and retail display trays. We have a team of expert designers to cover any of your needs, whether in new or pre-existing designs. Capabilities include many varieties of varnish (contrast, anti-humidity, grease-resistant, textured, aromatic); hot stamping; glossy and matte laminates; metallic inks; acetate window box inserts, and more.

Our development team is always working on the search for green alternatives such as vegetable inks, environmentally friendly varnishes, and Forest Stewardship Council®-certified cardboard, which helps preserve forests for future generations. For more information, visit www.ediprint.com.

Learn More